Metal roofs are durable, but screw holes can become a serious problem over time. Leaks from damaged or stripped screw holes lead to water damage and costly repairs. Homeowners and contractors need reliable solutions for metal roof screw hole repair.

Proper techniques prevent leaks and extend roof life. You can fix screw holes in metal roofs by replacing screws with larger sizes, applying high-quality sealants, using threaded inserts, or installing metal patches depending on the hole size and damage.

In this blog post, you’ll learn professional repair techniques, essential tools, best sealants, and when to call experts for help.

Key Takeaways

• Metal roof screw holes require immediate repair to prevent water damage and leaks

• Small holes can be fixed with larger screws or quality sealants

• Larger damaged areas need metal patches or threaded inserts for proper repair

• Coastal areas like Gulfport face higher risks of corrosion due to humidity and salt air

• Over-tightening screws is a common cause of leaks, especially with older metal roofs

• Professional metal roof maintenance reduces long-term repair costs

• Licensed contractors must follow Mississippi State Building Code for all roofing work

How Do You Fix Existing Screw Holes in Metal Roofs?

Existing screw holes in metal roofs can be repaired using three main methods depending on damage severity. Each method addresses specific problems like stripped screw holes or repairing loose screws.

Replace with a Larger Screw

Roof screw replacement with a larger diameter provides the simplest fix for small stripped holes. The bigger screw grips fresh metal material around the damaged area. This method works well when the hole hasn’t enlarged significantly.

You should use screws designed specifically for metal roofing applications. These fasteners include rubber washers that create watertight seals. Proper roofing screw installation prevents future leaks and maintains structural integrity.

Roofing washer replacement might be all you need if the screw itself remains tight. Old washers crack and lose their sealing ability over time. Fresh washers restore the waterproof barrier around fasteners effectively.

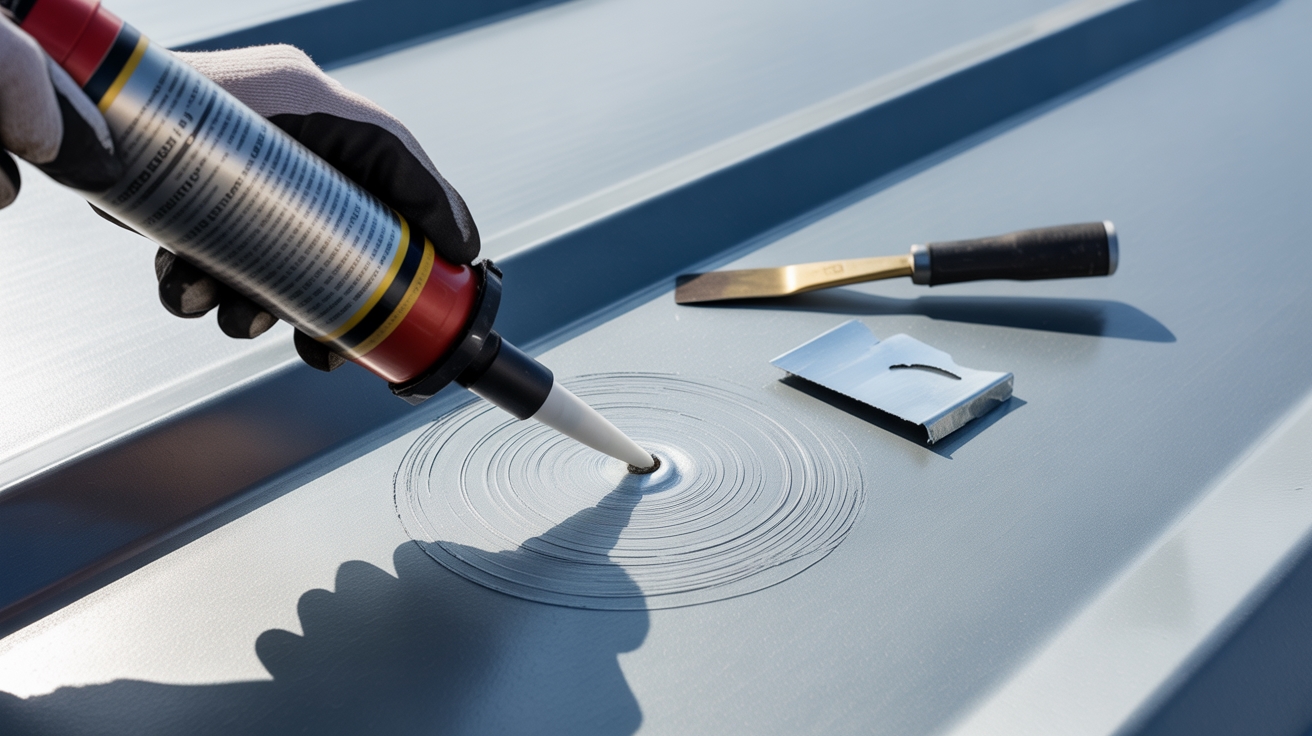

Apply Sealant

High-quality sealants offer excellent solutions for minor roof leak repair around existing screws. Roof screw hole sealant fills gaps between the fastener and metal panel. You should clean the area thoroughly before applying any sealing compound.

Roof sealing compounds work best when applied in dry conditions above 40 degrees. The sealant needs time to cure properly for maximum effectiveness. Case studies from Gulf Coast cities highlight that silicone and butyl sealants perform best in humid, salty environments.

Weatherproofing screw holes with sealant provides temporary protection for minor issues. This approach works well as part of regular metal roof maintenance routines. You can extend the life of your fasteners significantly with proper sealing.

Use a Threaded Insert (for Larger Holes)

Threaded inserts provide permanent fixes for significantly enlarged or damaged holes. These metal sleeves create new threads for screws to grip securely. Metal roof thread repair using inserts restores full holding power to compromised areas.

You need to drill out the damaged hole to accept the insert. The insert gets secured with sealant or epoxy for maximum stability. This technique qualifies as structural roof repair for serious fastener problems.

Screw hole enlargement from repeated removal and installation requires this stronger solution. Inserts prevent further damage to the metal panel itself. Professional contractors recommend this method for metal roof restoration projects.

How Do You Repair Unwanted or Larger Holes in Metal Roofs?

Larger holes in metal roofs require more substantial repair methods than simple screw replacement. Fixing metal roof holes that exceed standard screw sizes needs patching or specialized techniques.

Seal with High-Quality Sealant

Premium sealants can fill moderately sized holes when metal integrity remains intact. Screw hole filler products designed for roofing applications work better than general-purpose caulks. You must select products rated for exterior metal roof use.

The sealant must bond well to metal surfaces under various weather conditions. Waterproofing roof screws and surrounding areas prevents moisture infiltration. Multiple coats may be necessary for holes larger than a quarter inch.

Weather damage repair using sealant alone works best as a temporary roof repair solution. You should plan for more permanent fixes when conditions allow. Roof leak prevention requires monitoring sealed areas for signs of failure.

Use a Metal Patch

Metal roof patching provides the most reliable solution for holes too large for sealants. Metal patches match your roof material and thickness for proper repairs. Metal panel repair using patches maintains the roof’s structural integrity and appearance.

You should cut patches at least two inches larger than the damaged area. The patch gets secured with roofing screws around the perimeter and sealed completely. This method works well for metal roof damage repair from various causes.

Metal roofing tools like tin snips and drills make patch installation straightforward. You need to clean and prepare both surfaces before applying sealant. Metal roof repair kits often include pre-cut patches and appropriate fasteners.

Use Rivets and Sealant

Rivets combined with sealant create extremely strong repairs for larger damaged areas. Roof fastener alternatives like rivets don’t rely on threads that can strip. This combination prevents metal roof screw pullout in compromised areas.

You must drill properly sized holes for rivets through both the patch and roof panel. Rivets get installed with special tools that compress them for tight fits. Sealant applied before and after rivet installation ensures complete waterproofing.

Roof fastener repair using rivets works exceptionally well in high-wind coastal areas. Full roof coatings are recommended in Gulfport to protect against corrosion from coastal weather. This approach provides a permanent roof fix for serious damage.

What Are Important Tips for Metal Roof Screw Hole Repair?

Several critical considerations ensure successful metal roof screw hole repair projects. These tips help you avoid common mistakes that lead to future problems.

Safety First

Safety gear is essential for all roof repairs due to steep slopes and high winds common in the area. Personal protective equipment includes non-slip shoes, harnesses, and hard hats. Roof work presents serious fall risks that proper equipment mitigates.

You should never work on roofs during wet, windy, or icy conditions. Weather conditions in Mississippi can change quickly and create dangerous situations. Professional contractors carry liability insurance for added protection during repairs.

Emergency roof repair work still requires proper safety precautions despite urgency. You should secure the work area and use appropriate fall protection systems. Professional roof repair services have training and equipment for safe work.

Do Not Over-Tighten Screws

Over-tightening screws is a common cause of leaks in Gulfport, especially with older metal roofs. Excessive torque crushes the rubber washer and damages the metal panel. Roof screw torque should be sufficient to seal without deforming materials.

You can tell when a screw is properly tightened by washer compression. The washer should flatten slightly but not bulge around the screw head. Roof screw failure often results from installation errors rather than material defects.

Roofing screw installation requires experience to achieve proper tension consistently. Power tools should have torque settings adjusted for roofing applications. This practice prevents stripped screw holes from developing over time.

Consider a Full Coating

Roof coatings provide comprehensive protection for aging metal roofs with multiple problem areas. Metal roof restoration using coatings seals existing holes while preventing new ones. Metal roof restoration techniques can extend roof life by 10-20 years.

Coatings create seamless waterproof barriers over entire roof surfaces. Metal roof corrosion repair gets addressed as coatings seal and protect metal. This approach proves cost-effective compared to roof panel replacement in many situations.

Metal roof longevity increases significantly when protective coatings are applied properly. Gulfport, Mississippi follows state building codes for roof repairs, requiring compliance with local ordinances. Professional application ensures proper adhesion and coverage for maximum benefit.

What Tools Are Needed to Repair Screw Holes in Metal Roofing?

Metal roofing tools for screw hole repairs include both basic and specialized equipment. Proper tools make repairs easier and ensure professional-quality results for DIY metal roof repair projects.

Essential tools include cordless drills with adjustable torque settings for proper fastener installation. Socket sets with magnetic holders prevent dropped screws during roof work. Metal roofing tools like tin snips cut patches and trim damaged areas cleanly.

Caulking guns designed for heavy-duty sealants are necessary for applying roofing compounds. Wire brushes remove rust and debris from repair areas before sealing. Measuring tape and markers help ensure accurate patch sizing and roof screw spacing.

Safety equipment represents the most critical tool category for any roof work. Harnesses, lifelines, and anchor points prevent falls during repairs. Non-slip boots and gloves improve grip and protect against sharp metal edges.

Metal roof inspection tools like moisture meters identify hidden damage around screw holes. These devices detect leaks not visible from roof surfaces alone. Proper diagnosis prevents incomplete repairs that fail quickly after completion.

Roof repair materials should be gathered before starting work to avoid multiple trips. You need screws, washers, sealants, and patches appropriate for your specific roof. Metal roof repair kits often bundle necessary materials for convenience and compatibility.

Can You Prevent Screw Holes from Leaking in Metal Roofs?

Prevention methods significantly reduce the likelihood of screw hole leaks in metal roofs. Roof leak prevention starts with proper initial installation and continues with regular maintenance.

Roof screw patterns designed by engineers distribute loads evenly across roof panels. Following manufacturer specifications for fastener placement prevents stress concentrations. Preventing future screw holes requires respecting existing fastener layouts during repairs.

Quality fasteners with EPDM rubber washers provide superior sealing compared to cheaper alternatives. Waterproofing roof screws begins with selecting products rated for your climate conditions. Using incorrect sealants or improper installation can void warranties and lead to legal liability if water damage occurs.

Regular metal roof maintenance schedules catch small problems before they become major leaks. Annual inspections identify loose screws, damaged washers, and early corrosion signs. Proactive roofing washer replacement extends the life of existing fasteners significantly.

Metal roof reinforcement around problem areas distributes stresses that cause screw failures. Additional fasteners or structural supports prevent excessive movement during wind events. This approach proves particularly valuable in coastal areas with severe weather exposure.

Protective coatings applied over fasteners seal and shield them from environmental damage. These barriers prevent repairing rusted roof screws from becoming necessary later. Studies show metal roofs in Gulf Coast regions last longer when properly sealed and maintained, reducing long-term repair costs.

When Should You Replace Screws Versus Patching Metal Roof Holes?

Replacing screws is preferred for small holes, while patching is better for larger or corroded holes. The decision depends on hole size, metal condition, and surrounding damage extent.

Screw replacement works well when holes remain relatively small and metal around them stays intact. Oversize screw repair effectively addresses stripped screw holes up to about twice the original diameter. This method provides quick, economical fixes for isolated problems.

Patching becomes necessary when holes exceed three-eighths of an inch in diameter. Metal surrounding large holes often shows thinning, rust, or stress cracks. Metal panel repair using patches addresses these broader damage patterns comprehensively.

Roof screw extraction might reveal more extensive problems than visible from the surface. Corroded fasteners that break during removal indicate metal deterioration requiring patches. Repairing rusted roof screws often leads to discovering additional compromised areas nearby.

Roof repair cost comparisons favor screw replacement for minor issues and patching for major damage. Multiple closely-spaced damaged fasteners might warrant a single larger patch instead of individual repairs. Professional assessment helps determine the most cost-effective approach for your situation.

Metal roof damage repair decisions should consider long-term performance versus immediate costs. Patches provide more durable solutions for areas with recurring problems. Roof repair techniques selection impacts how long repairs last before requiring attention again.

What Sealants Work Best for Metal Roof Screw Hole Repairs?

Sealant selection critically affects metal roof screw hole repair success and longevity. Roof screw hole sealant must withstand extreme temperatures, UV exposure, and moisture.

Silicone sealants offer excellent adhesion to metal surfaces and remain flexible across temperature ranges. These products resist UV degradation and maintain sealing properties for many years. Case studies from Gulf Coast cities highlight that silicone and butyl sealants perform best in humid, salty environments.

Butyl rubber sealants provide superior waterproofing and work well in coastal environments. These compounds resist salt air corrosion better than many alternatives. Weatherproofing screw holes with butyl sealants proves particularly effective in Mississippi coastal regions.

Polyurethane sealants bond strongly to metal and create durable, flexible seals. These products handle roof movement from thermal expansion without cracking. Roof sealing compounds based on polyurethane technology offer long service lives.

You should avoid general-purpose caulks not rated for roofing applications on metal. These products often fail quickly under roof conditions and void warranties. No specific state law addresses screw hole repairs, but all roofing work must meet Mississippi State Building Code standards.

Metal roof restoration projects often use specialized coatings that seal multiple fasteners simultaneously. These products provide comprehensive protection beyond individual screw repairs. Professional contractors can recommend products appropriate for your specific roof type and climate.

Why Choose BSL Roofing for Your Mississippi Metal Roof Repairs?

BSL Roofing provides expert professional roof repair services throughout Mississippi’s coastal region. We are trusted roofing contractors in Mississippi with extensive experience in metal roof restoration techniques. Our team understands the unique challenges that coastal environments present to metal roofing systems.

Mississippi law requires roofing contractors to be licensed, ensuring repairs meet professional standards. Our licensed professionals follow all state building codes and local ordinances for safe, compliant work. We serve Gulfport, Mississippi and surrounding communities including Ocean Springs, Long Beach, Pass Christian, and Biloxi. Our service area extends to Long Beach, Waveland, D’Iberville, and other popular areas of Gulfport, Mississippi.

Licensed contractors in Gulfport must follow state regulations for all roofing repairs. BSL Roofing delivers quality metal roof damage repair backed by warranties and professional guarantees. Our team uses the best roof repair materials and proven techniques for lasting results. Contact us today for a free inspection and estimate on your metal roof screw hole repairs.